Cutting and stitching with love to details.

Purely handcrafted. An own sewing shop where everything is done by hand and where all individual wishes can be realised? This is what you can find in the Mastertent sewing workshops. With incredible skill, the experienced seamstresses process the high-quality tent fabric into a masterpiece.

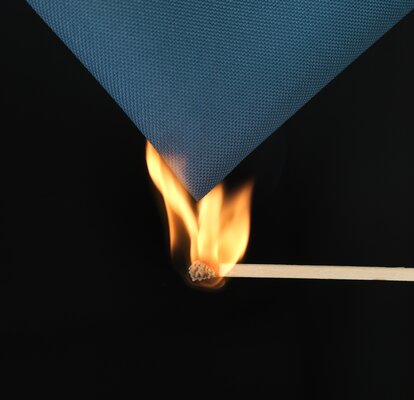

Extraordinary tension. The high-quality polyester fabric is:

- waterproof

- windproof

- fire-retardant (according to EN standard 13501-1)

The colour authenticity of the 12 standard colours was tested according to ISO criteria. Oxford 500 D is used for the roof of the S1.

Tear-resistant and colourfast. The polyester fabric Oxford 250D is used for the Series 1 and Series 2 sidewalls.

Compared to Oxford 500D, the fabric is slightly thinner, but still windproof, waterproof and fire retardant.